4 Simple Techniques For Bullcaster Co.,ltd

Wiki Article

The Only Guide to Bullcaster Co.,ltd

Table of ContentsSome Known Factual Statements About Bullcaster Co.,ltd Our Bullcaster Co.,ltd PDFsWhat Does Bullcaster Co.,ltd Do?The smart Trick of Bullcaster Co.,ltd That Nobody is Talking AboutLittle Known Facts About Bullcaster Co.,ltd.A Biased View of Bullcaster Co.,ltd

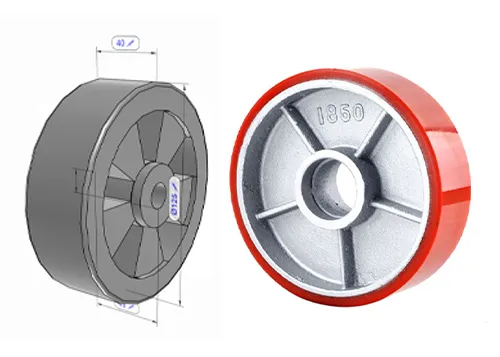

They are chemical, oil, and also acid immune due to the fact that they are made up of polycarbonate as well as mold-on rubber. While a soft tread allows wheels to surrender small debris and also is typically quieter than various other products, it also makes it harder to roll and reduces the wheel's general load capacity. Polycarbonate rubber, rubber step on iron core, and also polyurethane walk on plastic core are all usual soft step wheel wheels.They are also used in food service equipment, processing plants, and also other light to tool loads. Ferrous wheels give the highest possible tons capability, impact resistance, temperature array, as well as rollability of any caster wheel offered because of the solid structure it has. Ferrous wheels, as the name implies, are made from forged steel or cast iron, making it exceptional for rough situations such as stockrooms and also making factories where flooring defense is not a top priority.

Nevertheless, strong urethane wheels are one strategy to avoid these issues. The problem of step splitting up and core corrosion is decreased since the entire wheel is made of shaped urethane without core. Artificial wheels with a harder step have a reduced rolling resistance and also a higher effect stamina as well as dependability.

Some Known Questions About Bullcaster Co.,ltd.

While most artificial wheels are ideal for high-impact as well as harsh situations, they are louder than softer materials and are much less flexible when clashing with debris. Phenolic wheels, which are made from phenolic resin and also macerated canvas, are a regular selection for press pull applications. Phenolic wheels are strong and also withstand oil and also other chemicals, making mobility simpler.

These wheels have a solidity of 130 150 brinell. Birthing made use of on these wheels may include: a simple birthed, straight roller, as well as precision tapered roller. Flanged wheel wheels can operate within a temperature level of 800F given it has appropriate bearings and lubrication. This type of caster wheel can operate in the list below problems: moderate chemicals, oily as well as oily areas, as well as steel chips on the surface.

Not known Factual Statements About Bullcaster Co.,ltd

The strong wheels are unbreakable in regular use, can tolerate heats, and soak up shock as well as influence without failure. Forged steel wheels surpass ductile steel wheels in terms of load capability, impact stamina, and also rollability of all wheel wheels - https://www.nulled.to/user/5725772-bullcasterco. Created steel wheel wheels can be operated concrete and also smooth steel surface areas.Bearings that can be utilized consist of plain, tapered, Teflon, as well as roller bearings (heavy duty casters). These wheel wheels can run under the very same problems which are moderate chemicals, oily as well as oily areas, and steel chips on the surface area. These wheels are composed of a nylon and also glass combination as well as are engineered to hold up against severe temperatures.

Bullcaster Co.,ltd for Beginners

Tough rubber caster wheels bring around noise decrease as well as flooring security. Pneumatically-driven wheel wheels are well suited for aerospace and various other applications.These non-marking, non-conductive wheels supply outstanding floor protection. Gray iron castings are used to make these wheels. The lots is directed per face of the visit their website inverted angle iron track by the 90 grooves pierced into the face of the wheels. V-Groove wheels can also be utilized to manage the flow of a lots over substantial distances in a selection of procedures.

Another advantage of this kind of brake is that the actuation method can be made with the feet, which gets rid of driver strain from bending down to activate with a hand. casters manufacturer. These brakes can be mounted on a caster's leading or trailing side. Face call brakes work by pressing a plate onto the wheel's running surface making use of a threaded rod.

All about Bullcaster Co.,ltd

These brakes give a strong holding force and also are appropriate for sturdy applications. These brakes can be set up on a caster's leading or trailing edge. The drawback of this kind of brake is that it calls for the operator to flex over and tighten or loosen the brake by hand, which puts extra pressure on the driver and takes longer than a foot activated brake.

Securing and unlocking these brakes is simple and also can be finished with the operator's foot. They also use up extremely little area since they are affixed to the caster's side as well as fit within the caster wheel's swivel distance. The downside of these brakes is that they do not have a great deal of holding power therefore are better suited for light-duty situations.

The wheel application's operation and safety can be improved by picking the ideal brake layout. It will certainly additionally go over the maintenance of caster wheels.

What Does Bullcaster Co.,ltd Do?

Sturdy casters, on the other hand, are commonly seen in industrial plants, storage facilities, and also various other massive items that need mobility. Sturdy wheel wheels are used to move hefty work things, settings up, and tools in the aerospace as well as aircraft manufacturing process. Sturdy casters are an essential element of aircraft engine stands due to the fact that they permit the specialist to easily relocate and secure the work stand.Report this wiki page